Lamons Keeps You Running

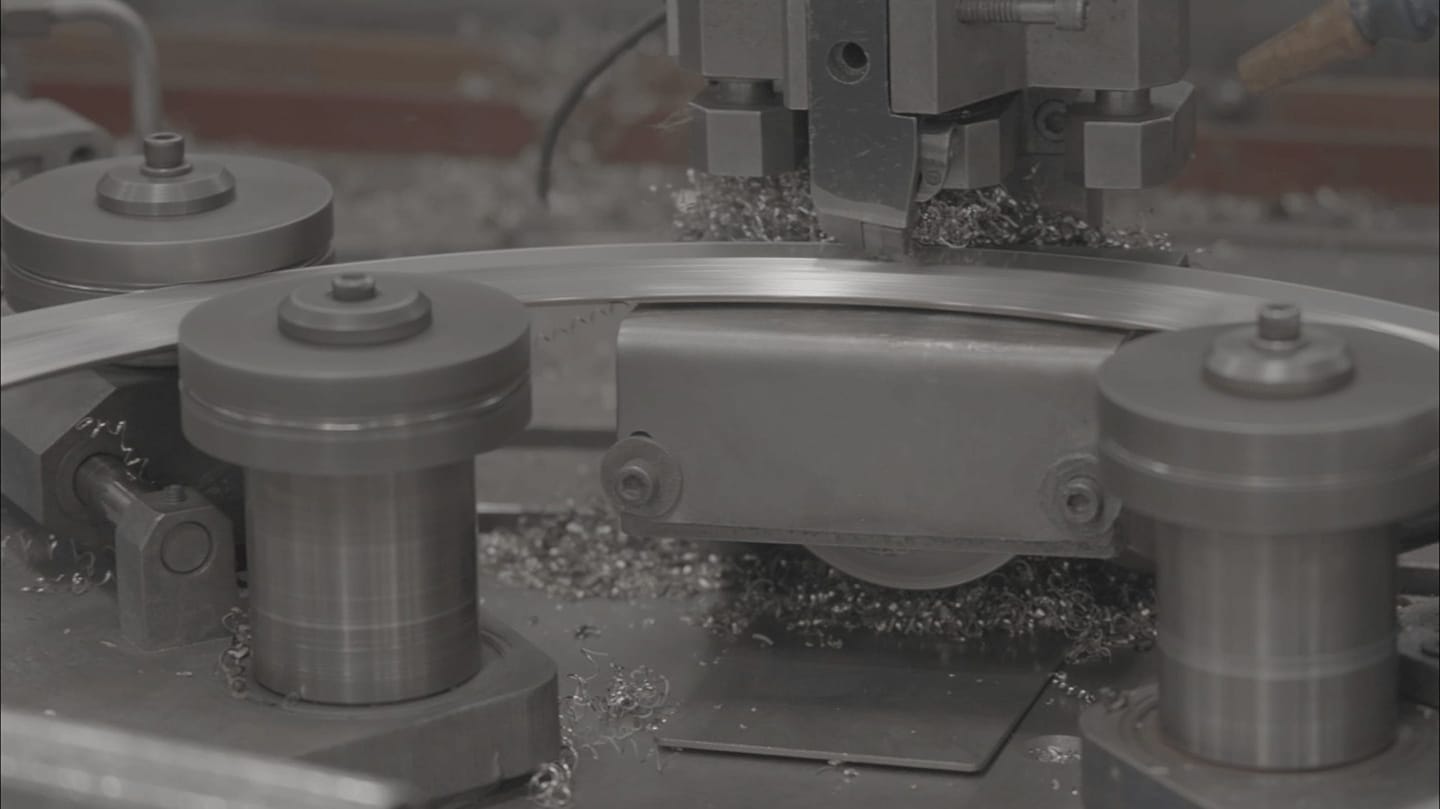

Safety sealing and attachment solutions built for you. From high-volume and automated to customized and one-of-a-kind.

Contact Our Experts

Our Legacy

As one of the largest privately held gasket, fastener, and hose manufacturers and distributors in the world, Lamons is the partner you can trust to deliver quality products whenever you need them — at consistently fair pricing. Since 1947, we’ve been providing industry-leading safety sealing and attachment solutions that help keep communities safe and drive progress across the world.

Your Innovation Partner

We believe progress is built on partnership. That’s why we’re available 24/7 with the fastest response time in the industry. We seamlessly handle high-volume and quick-turn needs for both standard components and one-of-a-kind engineered solutions. Learn how we’re setting the standard for quality and ingenuity.

Accelerating renewable energy

We’re committed to being the manufacturer of choice for the renewable energy industry, by engineering custom sealing and attachment solutions for wind energy, hydro energy, geothermal energy, and alternative fuels sectors. Regardless of industry, we help every customer increase efficiency and pursue lower emissions.

Committed to Safety and Sustainability

Through constant improvement of our products, processes, and services, we support the safe operations of essential industries and partner with forward-thinking customers on innovations that protect the environment for future generations.

Industries

Lamons can help you solve the urgent needs you face today while helping you scale for tomorrow. Learn how we customize our solutions and technical expertise around your industry’s unique challenges.

Our Offerings at a Glance

Get to know our signature products, customer-centric solutions, and certifications through this brief overview of our company.