Building on the proven success of the trusted HTG design, Lamons XTG pushes the temperature resistance boundary from 1500°F (815°C) to 1800°F (982°C). This advancement represents more than just an increase in capability— it’s a testament to Lamons commitment to innovation, safety, and reliability in the most demanding environments.

The Next Evolution in High-temperature Sealing

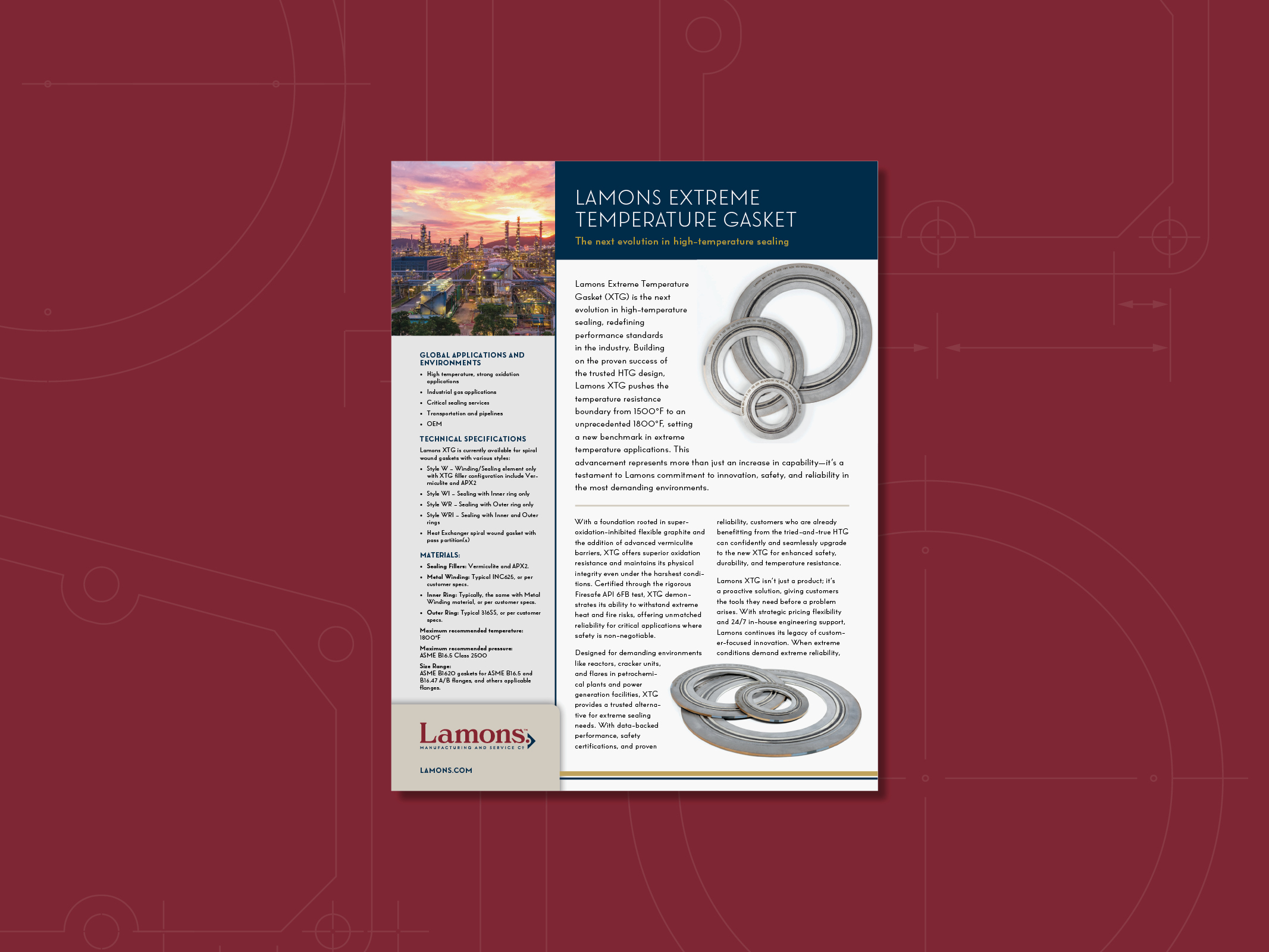

Lamons Extreme Temperature Gasket (XTG) is the next evolution in high-temperature sealing, redefining performance standards in the industry. Building on the proven success of the trusted HTG design, Lamons XTG pushes the temperature resistance boundary from 1500°F (815°C) to 1800°F (982°C), setting a new benchmark in extreme temperature applications. This advancement represents more than just an increase in capability— it’s a testament to Lamons commitment to innovation, safety, and reliability in the most demanding environments.

With a foundation rooted in super-oxidation-inhibited flexible graphite and the addition of advanced vermiculite barriers, XTG offers superior oxidation resistance and maintains its physical integrity even under the harshest conditions. Firesafe API 6FB certified, XTG demonstrates its ability to withstand extreme heat and fire risks, offering unmatched reliability for critical applications where safety is non-negotiable.

Designed for demanding environments like reactors, cracker units, and flares in petrochemical plants and power generation facilities, XTG provides a trusted alternative for extreme sealing needs. With data-backed performance, safety certifications, and proven reliability, customers who are already benefitting from the tried-and-true HTG can confidently and seamlessly upgrade to the new XTG for enhanced safety, durability, and temperature resistance.

Lamons XTG isn’t just a product; it’s a proactive solution, giving customers the tools they need before a problem arises. With strategic pricing flexibility and 24/7 in-house engineering support, Lamons continues its legacy of customer-focused innovation. When extreme conditions demand extreme reliability, the XTG is sure to deliver unparalleled performance and safety. By staying ahead of market needs and proactively developing the XTG, Lamons offers a solution that’s not only ready for today’s challenges but also anticipates future demands.

Lamons XTG is more than a product—it’s a promise of trusted innovation, safety, and performance. Whether you’re upgrading from HTG or seeking a robust solution for the most extreme conditions, XTG delivers. Engineered for extremes, certified for safety.

Global Applications and Environments

- Fluid catalytic cracking units (FCCs)

- Furnaces

- Coker units

- Energy production

- OEM

Technical Specifications

Lamons XTG is currently available for spiral wound gaskets with various styles:

- Style W – Winding/sealing element only with XTG filler configuration including Vermiculite and APX2

- Style WI – Sealing with inner ring only

- Style WR – Sealing with outer ring only

- Style WRI – Sealing with inner and outer rings

- Heat Exchanger spiral wound gasket with pass partition(s)

Materials

- Sealing Fillers: Vermiculite and APX2

- Metal Winding: Typical INC625, or per customer specs

- Inner Ring: Typically, the same with metal winding material, or per customer specs

- Outer Ring: Typical 316SS, or per customer specs

- Maximum recommended temperature: 1800°F (982°C)

- Maximum recommended pressure: ASME B16.5 Class 2500

- Size Range: ASME B1620 gaskets for ASME B16.5 and B16.47 A/B flanges, and other applicable flanges