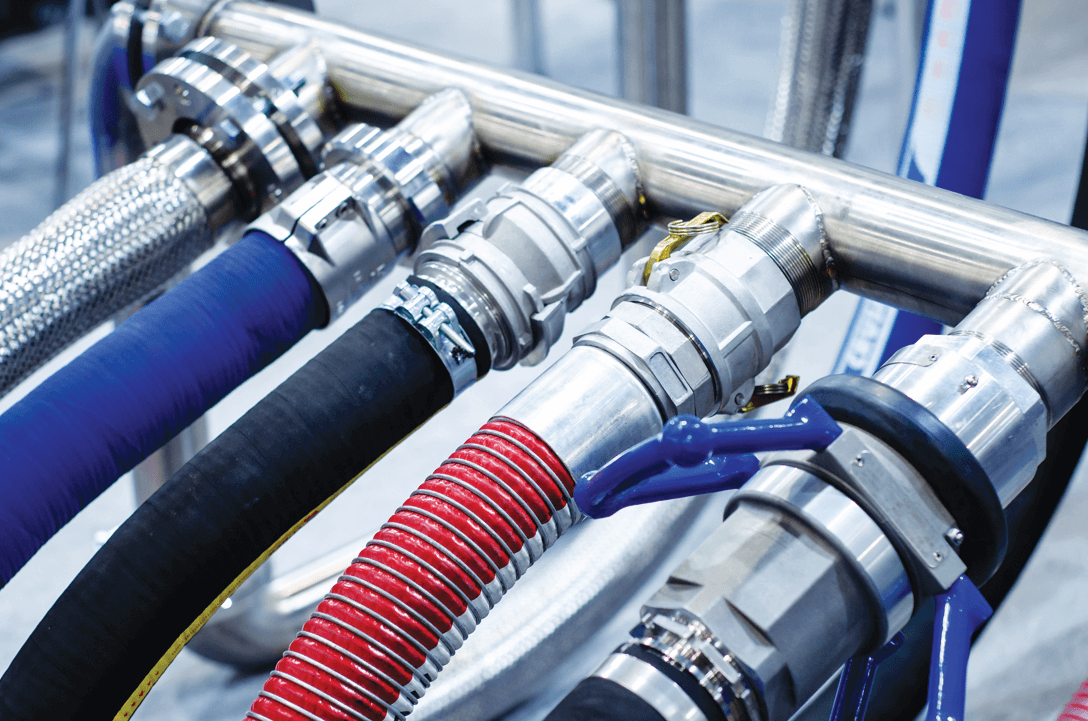

Hose Design and Selection: The S.T.A.M.P.E.D. Method

Proper hose selection is crucial to the smooth and safe operations of many essential industries. Hoses are often used to move harmful chemicals or materials at extreme temperatures, so they must be able to pass rigorous pressure and leak testing.

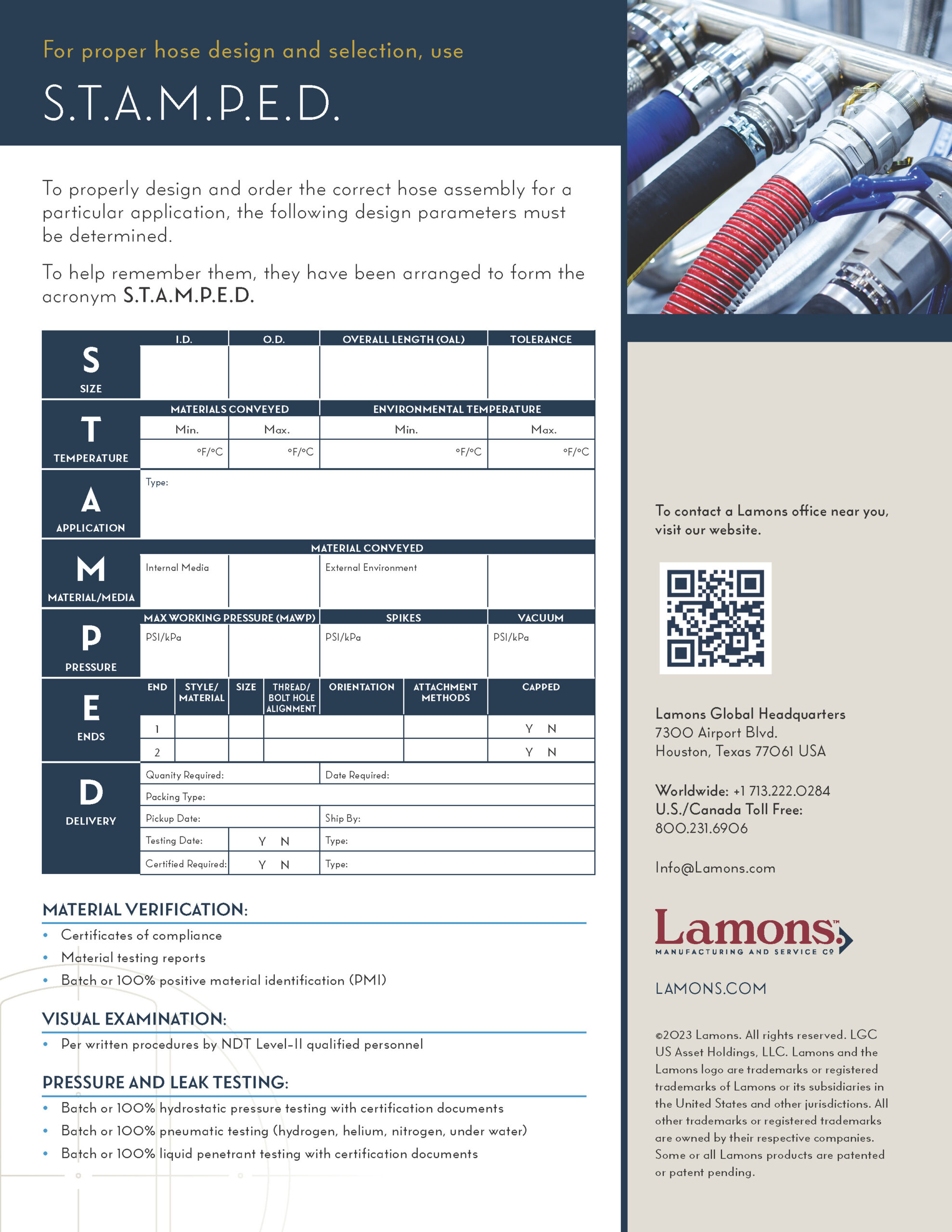

The S.T.A.M.P.E.D guide is a tried-and-true industry method you can use to select the right hose for your application. It covers seven simple factors that will impact the specific hose you need.

The acronym “S.T.A.M.P.E.D” stands for:

- Size

- Temperature

- Application

- Material/Media

- Pressure

- Ends

- Delivery

As an industry leader in safety sealing solutions, Lamons is dedicated to helping customers streamline their operations by offering gaskets, fasteners, and hoses that set the standard for quality. Whether you need a rubber or metal hose, our goal is to share our expertise in manufacturing standard and customized sealing solutions to guide you through hose design and selection. Let’s walk through the seven factors of S.T.A.M.P.E.D. and what they mean.

Size

Hoses can be multiple inches in diameter and a hundred feet long. To ensure a perfect fit, you’ll need to determine four size measurements:

- Inner Diameter (I.D.)

- Outer Diameter (O.D.)

- Overall Length (OAL)

- Tolerance

Tolerance is typically determined by overall length of the entire hose assembly. Once you have measured overall length, consult ISO standards for corresponding tolerances.

Temperature

To achieve reliable hose performance, the material and design of your hose must be tailored to your individual temperature factors. Extreme high temperatures can cause weakening, melting, or other failure of an incorrect hose assembly, while extreme low temperatures can cause stiffening and cracking. You’ll need to determine the minimum and maximum temperature range of the materials conveyed inside the hose, as well as the min-max temperature range of the hose’s surrounding environment.

- Min. °F/°C of materials conveyed

- Max. °F/°C of materials conveyed

- Min. °F/°C of environmental temperature

- Max. °F/°C of environmental temperature

Application

Hoses play a crucial role in many application scenarios, from petrochemical plants to oilfields to construction sites. Your application may involve specific compliance requirements, and may also help you determine whether you should choose a standard or custom hose assembly. Just by knowing your application environment, an expert hose manufacturing partner can start to guide you towards the best solution for your needs.

Material/Media

One of the most important factors to consider during hose design and selection is material. Whether you’re conveying sanitary food and beverage, small molecular gases, or corrosive chemicals, your hose must be designed to match. The material of the hose’s surrounding environment will also help narrow down the type of assembly you will need. Here are the two material factors you need to identify:

- Internal Media

- External Environment

Pressure

Hoses can be designed to withstand different pressure requirements. In fact, they can be rated for full vacuum, high or low pressure applications. To know what pressure rating you’ll need, you must determine three pressure factors, all of which can be measured in pound-force per square inch (PSI) or kilopascals (kPa).

- Max. Allowable Working Pressure (MAWP)

- Spikes

- Vacuum

MAWP is the maximum pressure a system can handle in normal operation without risking failure of the system or equipment. Spikes, also known as “burst pressure,” refers to sudden system pulses that could potentially lead to failure if your hose assembly isn’t designed to account for it.

Ends

The right hose isn’t perfect unless it is properly certified, shipped, and delivered on time. Let your hose supplier know the relevant details regarding delivery, including any special packaging requirements or traceability needs. Here is a list of delivery-related information you should determine:

- Style/material

- Size

- Thread/Bolt Hole Alignment

- Orientation

- Attachment Methods

- Capped (Yes or No)

Common materials include aluminum, plated steel, stainless steel, PVC, and more. Common attachment methods include one-piece or two-piece permanently attached hydraulic fittings, as well as two-piece fittings that can be attached in the field without a crimping machine. To ensure your new hose can be successfully installed, make careful note of the orientation angle of your fittings at both ends.

Delivery

The right hose isn’t perfect unless it is properly certified, shipped, and delivered on time. Let your hose supplier know the relevant details regarding delivery, including any special packaging requirements or traceability needs. Here is a list of delivery-related information you should determine:

- Quantity Required

- Date Required

- Packing Type

- Pickup Date/Ship By Date

- Testing Date (Yes or No)

- Testing Type (If Yes)

- Certification Required (Yes or No)

- Certification Type (If Yes)

Lamons is dedicated to providing our customers with quality assurance and peace of mind. We verify materials through certificates of compliance, material testing reports, and batch or 100% positive material identification (PMI). Our visual examinations are conducted according to written procedures by NDT Level-II qualified personnel. Our pressure and leak testing includes batch or 100% hydrostatic, pneumatic, and liquid penetrant testing.

Choose A Hose Manufacturing Partner Your Can Trust

When it comes to choosing the best hose for your application, the S.T.A.M.P.E.D. system is an absolutely critical list of requirements to share with your hose manufacturing partner. At Lamons, we’re focused on understanding your needs and exceeding your performance expectations. Our team will be there every step of the way, from hose assembly and installation to inventory management and preventative maintenance. If you have questions about hose assembly and selection, we’re here to help.