Semi-Metallic Gaskets

Semi-Metallic GasketsExtreme Temperature Gasket (XTG)

High Temperature Gaskets

Lamons Extreme Temperature Gasket (XTG) is the next evolution in high-temperature gasket sealing, pushing the limits of performance and reliability. XTG builds on the trusted HTG (High-Temperature Gasket) design by increasing temperature resistance from 1500°F (815°C) to 1800°F (982°C)—a 20% improvement in thermal endurance that reaches the highest industry standard. Engineered with super-oxidation-inhibited flexible graphite and advanced vermiculite barriers, it offers superior oxidation resistance while maintaining integrity in the harshest conditions. Certified through the rigorous Firesafe API 6FB Type 2 test, XTG ensures safety in critical applications like reactors, cracker units, and flares in petrochemical and power generation facilities. With seamless compatibility for existing HTG users, strategic pricing flexibility, and 24/7 in-house engineering support, Lamons XTG high temperature gasket delivers unmatched durability, safety, and performance—engineered for extremes, certified for safety. Contact Lamons today to discuss industrial high temperature gaskets for your unique application.

Benefits of Lamons® XTG High-Temperature Gasket

Superior Oxidation Barrier

In high-temperature refinery applications like coker units (operating between 900–1,000 °F, 480–540°C), traditional gaskets degrade due to oxidation. Lamons solution— super-oxidation-inhibited flexible graphite and advanced vermiculite barriers to nearly eliminate graphite oxidation that retains physical integrity even under harsh, high temperature conditions.

The XTG’s innovative design features a dual-filler configuration:

- Oxidation-resistant flexible graphite

- Inner and outer protective vermiculite barriers

Together, these materials maintain seal integrity in environments where standard graphite gaskets deteriorate rapidly. This makes the XTG ideal for oxidative and high-cycle thermal conditions where long-term reliability is critical for performance and safety.

API-Approved Safety Certification

The XTG is certified under API 6FB Type 2 for firesafe performance. This third-party qualification ensures reliable sealing even in fire-prone environments such as reactors, cracker units, flares, and hydrocarbon processing systems. The XTG high temperature industrial gasket is purpose-built for applications in the petrochemical and power generation sectors.

Seamless Upgrade From Lamons® HTG

For existing customers using Lamons® HTG (High Temperature Gasket) products, the Extreme Temperature Gasket offers an easy, drop-in replacement that enhances performance without requiring redesign or flange modification. It is available in the same spiral wound gasket styles (W, WI, WR, WRI) and exchanger configurations and uses familiar alloys such as Inconel 625 for windings and 316 stainless steel for outer rings.

XTG offers straight equivalent service to current marketed 1800° vermiculite-based spiral wound gasket and often comes with X-750 heat treated material.

Applications for High Temperature Gaskets & Seals

Lamons Extreme Temperature Gasket is engineered to absorb mechanical movement and stress without cracking or losing sealing pressure. XTG is ideal for systems exposed to extreme heat, oxidation, thermal shock, and chemical corrosion, including:

- Petrochemical Reactors & Flare Systems

- Delayed Coker Units

- Fluid Catalytic Cracking (FCC) Units/Cracker Units

- Industrial Furnaces

- Superheaters & Heat Exchangers in Power Generation

- Energy Production

- OEM

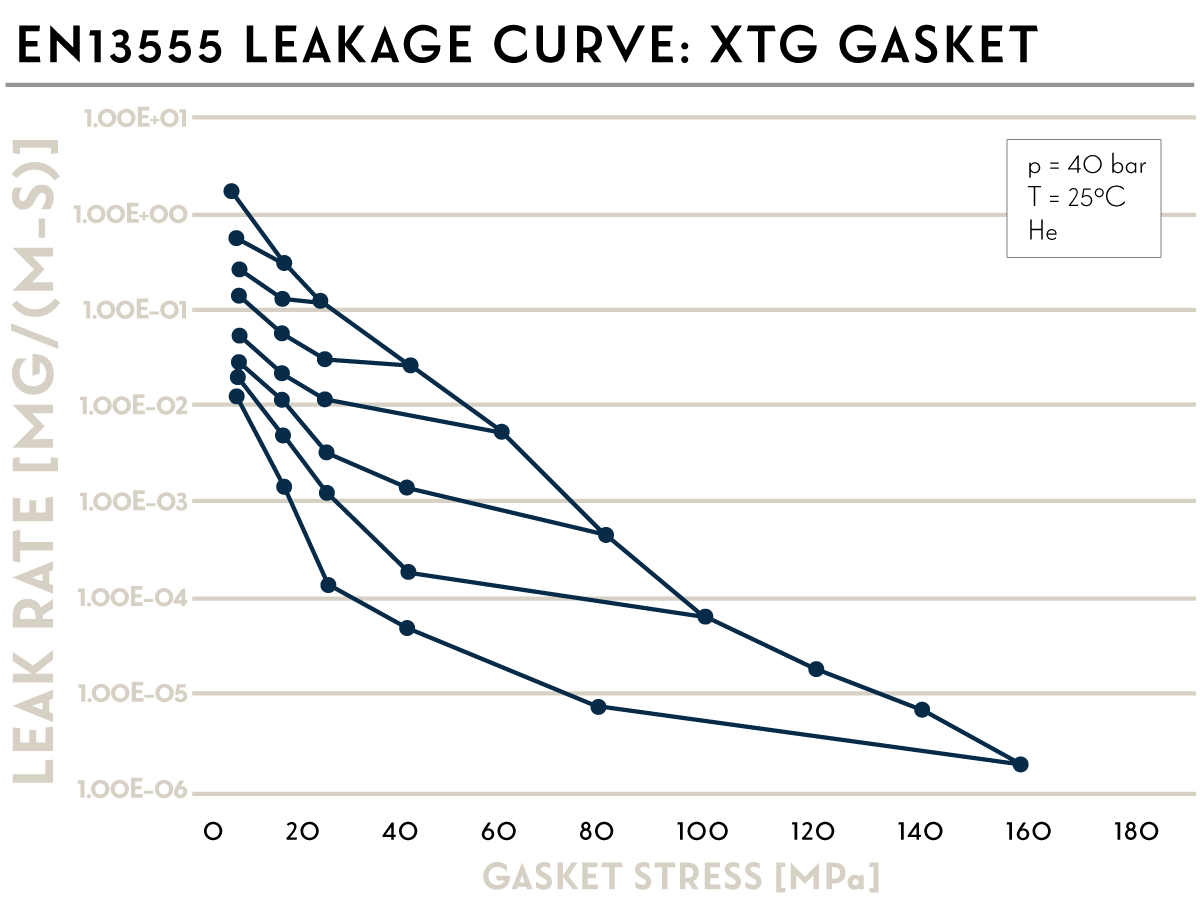

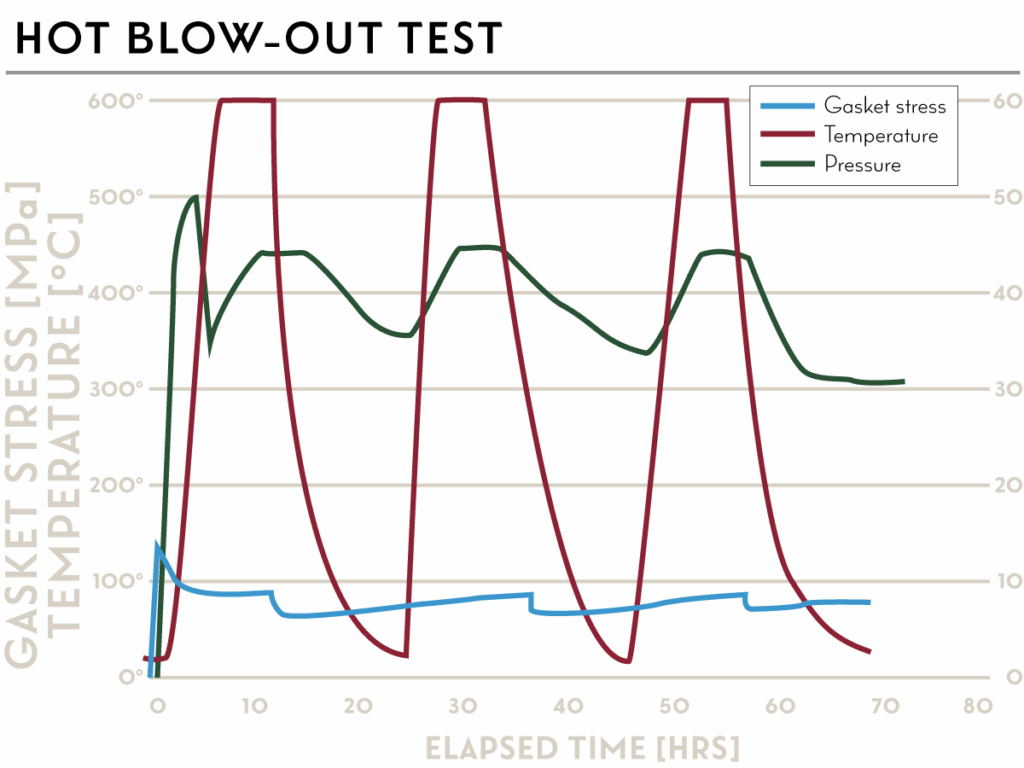

Hot Blow-Out Test for the Extreme Temperature Gasket (XTG) shows how the XTG gasket performs under extreme, fluctuating conditions over time, designed to simulate real-world thermal and pressure cycling. Over the course of 70 hours, gasket stress remains stable while withstanding multiple high-temperature cycles without significant pressure loss.

Engineering Support & Global Reach

Lamons backs XTG with comprehensive customer support:

- 24/7 engineering assistance for application guidance and installation

- Custom gasket engineering services for unique sealing needs

- Field services, including troubleshooting, on-site support and training

- Global manufacturing and inventory to ensure quick turnaround and regional availability

Lamons Extreme Temperature Gasket (XTG) — The Next Evolution in High-Temperature Sealing

Supported by Lamons global manufacturing footprint and 24/7 engineering assistance, XTG delivers reliable performance with fast availability, ensuring your most demanding applications stay sealed, secure, and safe.

For technical specifications, application support, or a product consultation, contact Lamons today or see our XTG Data Sheet for additional information.

Interested in upgrading your system’s high-temperature sealing performance? Connect with Lamons to request a quote or speak directly with our gasket engineering specialists for expert support and solutions tailored to your system.

Lamons XTG is currently available for spiral wound gaskets with various styles:

- Style W – Winding/Sealing element only with XTG filler configuration include Vermiculite and APX2

- Style WI – Sealing with Inner ring only

- Style WR – Sealing with Outer ring only

- Style WRI – Sealing with Inner and Outer rings

- Heat Exchanger spiral wound gasket with pass partition(s)

- Maximum recommended temperature: 1800°F

- Maximum recommended pressure: ASME B16.5 Class 2500

- Size Range: ASME B1620 gaskets for ASME B16.5 and B16.47 A/B flanges, and other applicable flanges.

- Sealing Fillers: Vermiculite and APX2.

- Metal Winding: Typical INC625, or per customer specs.

- Inner Ring: Typically, the same with Metal Winding material, or per customer specs.

- Outer Ring: Typical 316SS, or per customer specs.