The ISOGUARD sealing/isolating gasket system is designed for general applications where electrical flange isolation and corrosion control are required on pipes containing water/ wastewater, gas, natural gas, oil, and other hydrocarbon-based medias up to 302°F (150°C).

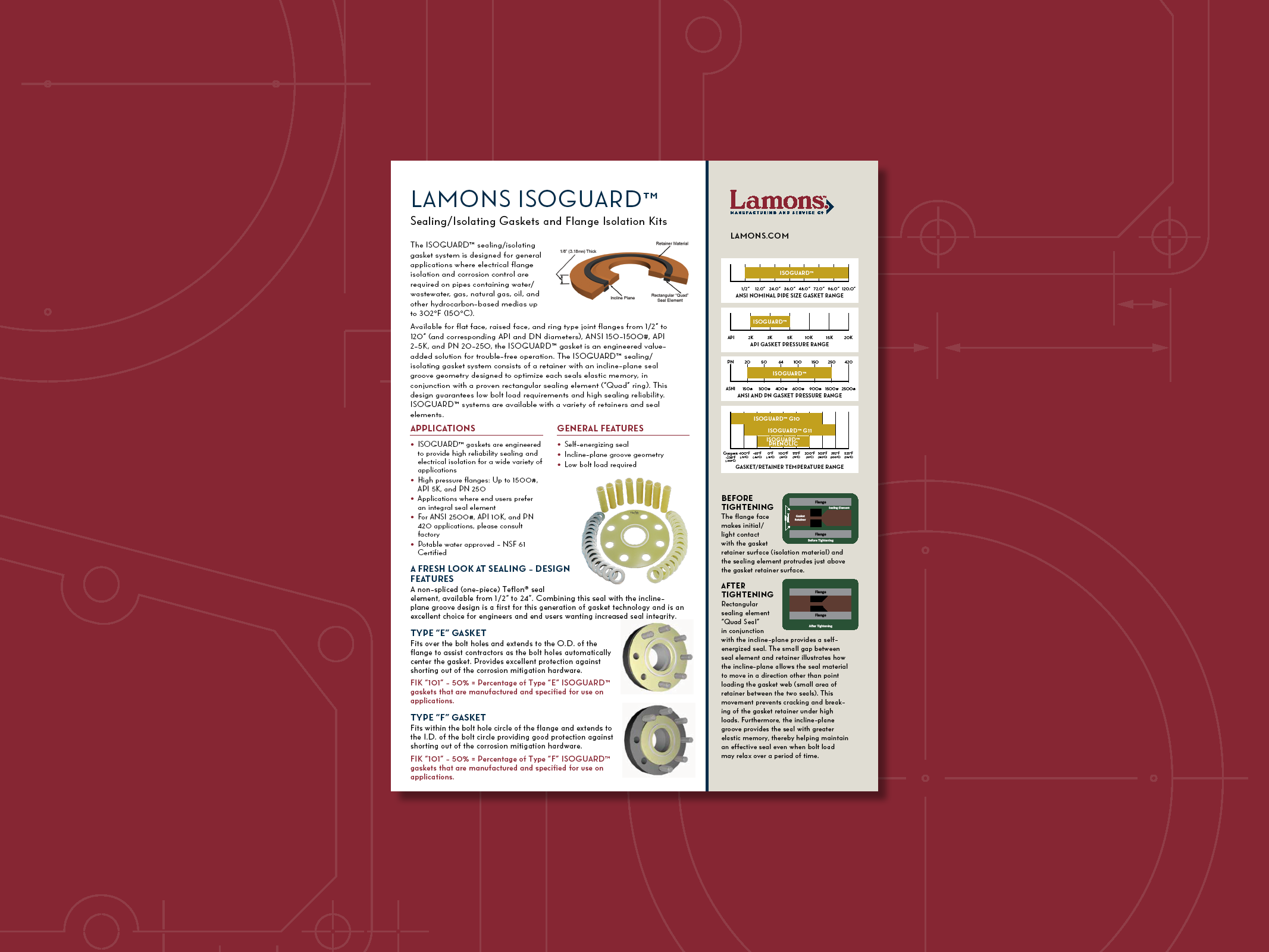

Available for flat face, raised face, and ring type joint flanges from 1/2” to 120” (and corresponding API and DN diameters), ANSI 150-1500#, API 2-5K, and PN 20-250, the ISOGUARD™ gasket is an engineered valueadded solution for trouble-free operation. The ISOGUARD™ sealing/ isolating gasket system consists of a retainer with an incline-plane seal groove geometry designed to optimize each seals elastic memory, in conjunction with a proven rectangular sealing element (“Quad” ring). This design guarantees low bolt load requirements and high sealing reliability. ISOGUARD™ systems are available with a variety of retainers and seal elements.

Applications

- ISOGUARD™ gaskets are engineered to provide high reliability sealing and electrical isolation for a wide variety of applications

- High pressure flanges: Up to 1500#, API 5K, and PN 250

- Applications where end users prefer an integral seal element

- For ANSI 2500#, API 10K, and PN 420 applications, please consult factory

- Potable water approved – NSF 61 Certified

General Features

- Self-energizing seal

- Incline-plane groove geometry

- Low bolt load required

A Fresh Look at Sealing – Design Features

A non-spliced (one-piece) Teflon® seal element, available from 1/2” to 24”. Combining this seal with the inclineplane groove design is a first for this generation of gasket technology and is an excellent choice for engineers and end users wanting increased seal integrity.

Type “E” Gasket

Fits over the bolt holes and extends to the O.D. of the flange to assist contractors as the bolt holes automatically center the gasket. Provides excellent protection against shorting out of the corrosion mitigation hardware.

FIK “101” – 50% = Percentage of Type “E” ISOGUARD™ gaskets that are manufactured and specified for use on applications.

Type “F” Gasket

Fits within the bolt hole circle of the flange and extends to the I.D. of the bolt circle providing good protection against shorting out of the corrosion mitigation hardware.

FIK “101” – 50% = Percentage of Type “F” ISOGUARD™ gaskets that are manufactured and specified for use on applications.

Retainer Material

- G10, G11, Phenolic

- Retainer Thickness 1/8” (0.125”)(3.18 mm)

Note: Consider G10 material for nominal pipe sizes of 12-inch and larger or ANSI pressure class 600# and higher.

Seal Element Materials

- Teflon®, Nitrile, Silicone, Viton®, EPDM

Facts

- Based on an industry proven design

- Enhanced with innovative engineered features

- Cycled tested at 10,000 psi at ambient temperature

- Made in the USA

- Tested to Shell Certification Standards

- WRAS Approved

- DNV-GL Approved

- NSF 61 Certified

ISOGUARD Flange Isolation Kits

For a flange isolation kit, sleeves and washers are needed. Generally, 95% of ISOGUARD gasket flange isolation kits are sold with G10 sleeves and G10 double washer sets when specified with a G10 retainer gasket.

Suggested Sleeve/Washer Sets

SD = Standard (G10 sleeves, steel ZP washers, and G10 washers) – double washer set. NOTE: Use with G10 gasket material.

ED = Economy (mylar sleeves, steel ZP washers, and phenolic washers) – double washer set. NOTE: Use with phenolic gasket material.