Lamons is proud to have partnered with Modumetal to provide our customers with NanoGalv®, a surface coating technology designed specifically for corrosion resistance in aggressive marine and coastal environments. This zinc-nickel nanolaminate technology provides superior corrosion resistance across a broad range of fastener applications at a thickness within standard thread allowances, so no over tap is required for thread fit. It has excellent durability and is not damaged by standard installation tools or practices.

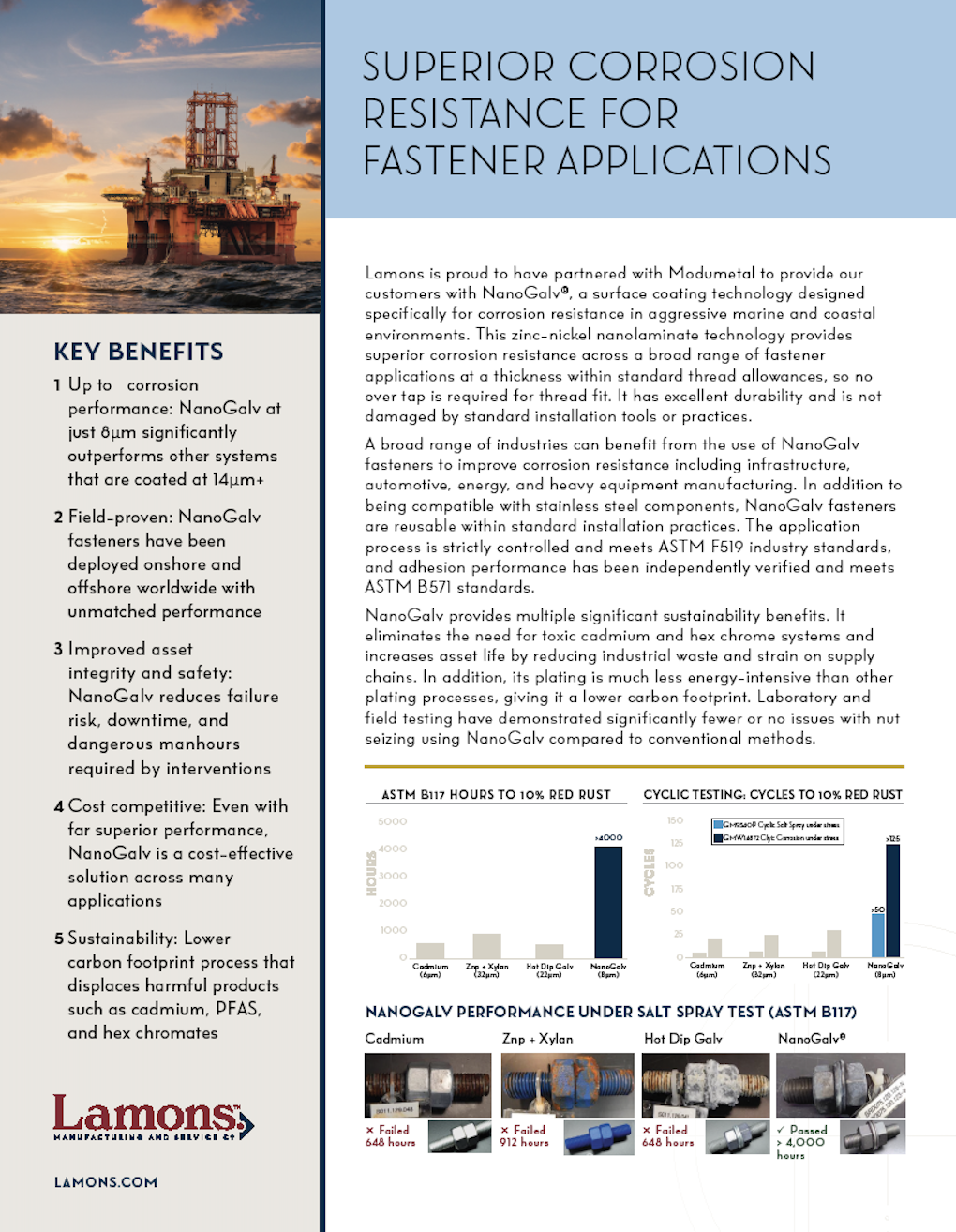

A broad range of industries can benefit from the use of NanoGalv fasteners to improve corrosion resistance including infrastructure, automotive, energy, and heavy equipment manufacturing. In addition to being compatible with stainless steel components, NanoGalv fasteners are reusable within standard installation practices. The application process is strictly controlled and meets ASTM F519 industry standards, and adhesion performance has been independently verified and meets ASTM B571 standards.

NanoGalv provides multiple significant sustainability benefits. It eliminates the need for toxic cadmium and hex chrome systems and increases asset life by reducing industrial waste and strain on supply chains. In addition, its plating is much less energy-intensive than other plating processes, giving it a lower carbon footprint. Laboratory and field testing have demonstrated significantly fewer or no issues with nut seizing using NanoGalv. compared to conventional methods.

NanoGalv even at a 3.5µm coating thickness, outperforms traditional ZnNi coatings at thicknesses of 12-14µm.

Superior performance at a lower coating thicknesses eliminates the need for overlapping of critical parts and enables coating of non-fastener parts with a complicated geometries.

NanoGalv withstands all hydrogen embrittlement tests, as tested under ASTMF519-13.