Gaskets

GasketsNon-Metallic Gaskets

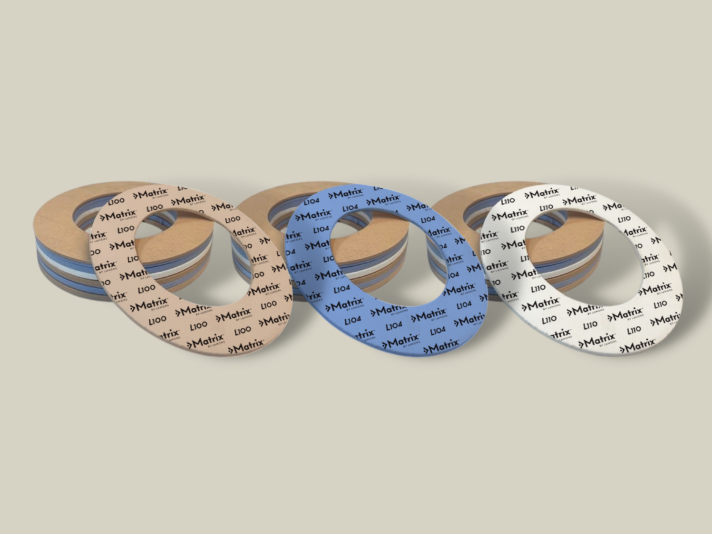

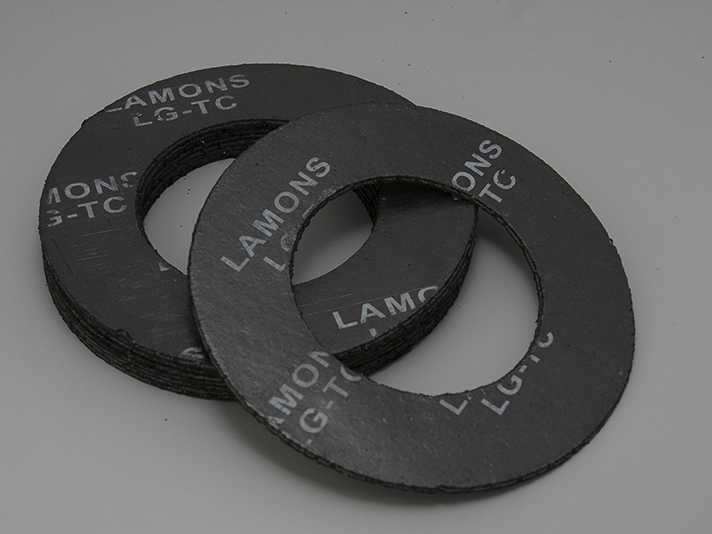

No matter the pressure class or temperature range of your application, Lamons has the right sealing solution for you. Our non-metallic gaskets are designed to meet the highest quality standards and perform in low to moderate pressure class applications. As part of our strategy to supply our customers with a wider range of sheet gasket products, we offer a variety of non-metallic gasket materials, including elastomeric and fiber gaskets, compressed non-asbestos gaskets, PTFE gaskets, and more.

Applications

Benefits

- Wide Service Temperature Range

- Low to Moderate Pressure Applications

- Severe Chemical Services

- Petroleum & Chemical Upstream, Midstream and Downstream

- Piping & Vessels

- Valves

- Pumps

- Wide variety of sizes, geometries and materials available

- Color-coded for easy material identification

- Compatible for a wide range of flange surface finishes

- Reduces fugitive emission, creep and cold flow characteristics

- Chemical resistance charts and data sheets available