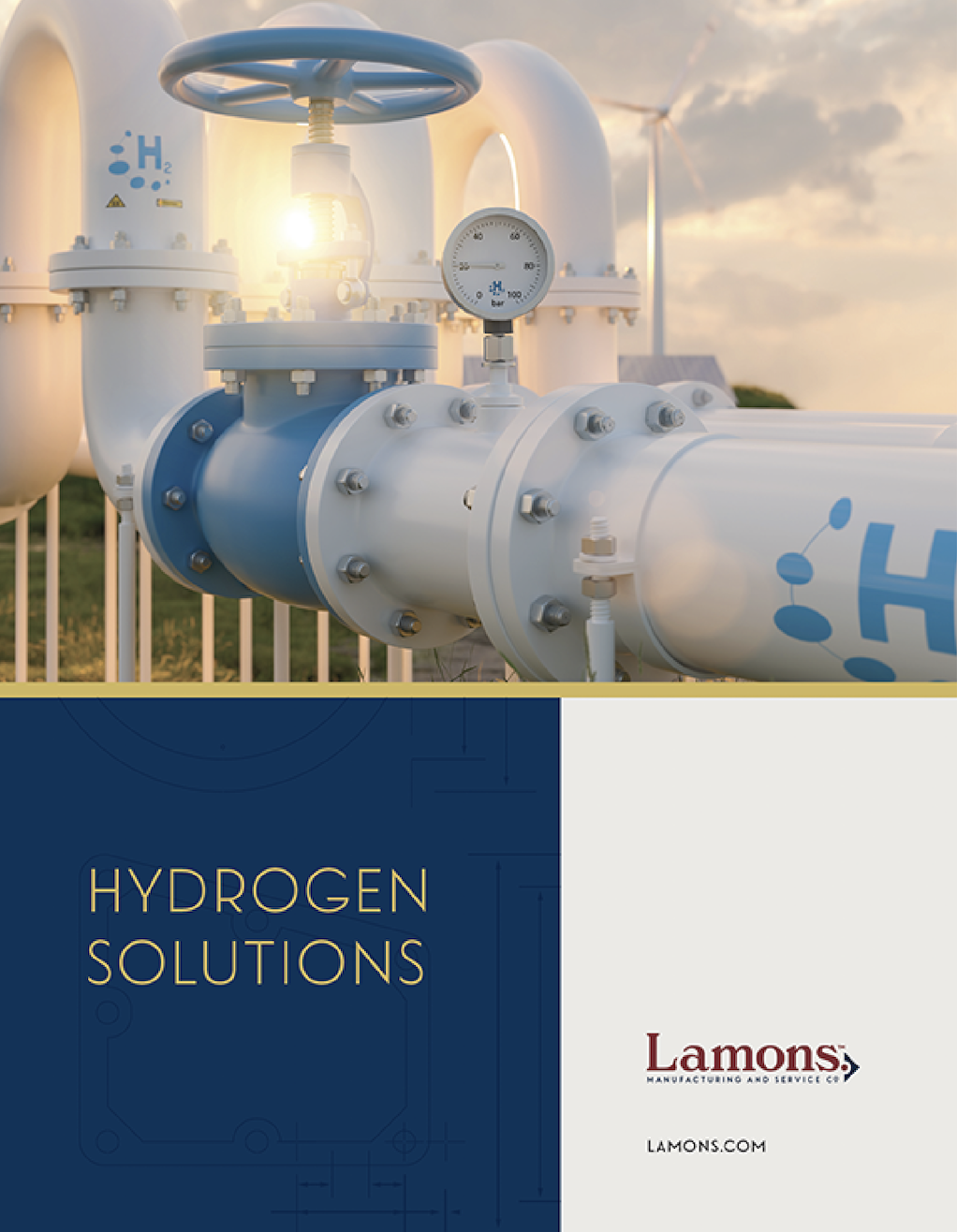

Hydrogen applications require well-designed, expertly-engineered mechanical components to handle hydrogen’s volatile and combustible nature. At Lamons, we understand this well and have the safety sealing and attachment solutions that can stand up to the rigors of hydrogen production, storage, transportation, and distribution.

Lamons supports all industries actively pursuing low-carbon energy alternatives with hydrogen and adopting carbon capture and sequestration (CCS) technologies into their operations. With over 75 years of manufacturing and engineering expertise, we offer an extensive product portfolio for the hydrogen market. Our wide selection of gaskets, fasteners, and assembled hoses and fittings make us a true one-stop resource for your hydrogen safety sealing and attachment solutions. When you need quality products on time to keep production moving and your team safe, Lamons has the solution. Lamons…manufacturing today for the industries of tomorrow.

A Focus on Quality Products

As the hydrogen market expands in breadth of application, so do Lamons engineered solutions, which are designed to address safety concerns and the range of temperature and pressure requirements for the entire hydrogen value chain.

Gaskets

All our hydrogen-suitable gaskets are rated for ASME B16.5 flanges, as well as custom flanges, and have been tested with the EN-13555 leakage test.

Lamons® SpiraSeal® Gasket Family consists of assorted spiral wound gaskets that address a range of applications. They are extremely popular due to the wide variety of available styles and sizes. These gaskets can be fabricated of any metal that is available in thin strips and can be welded. They can be used against virtually any corrosive medium, dependent upon the choice of the metal and filler, and they can be used over the complete temperature range from cryogenic to approximately 2000ºF (1093ºC). This type of gasket can be used in all pressures from vacuum to the standard 2500 pressure class flange ratings. Spiral wound gaskets can also be manufactured with variable densities (i.e., relatively low-density gaskets for vacuum service up to extremely high-density gaskets having a seating stress of approximately 40,000 psi [275 MPa]).

Lamons® CorruKamm® Gasket Family has gaskets with a revolutionary design that uses Kammprofile technology with a heavy substrate capable of extreme load-bearing properties combined with a precisely located corrugated pattern that greatly enhances deflection and compression under load. This makes the gasket more forgiving when perfect alignment and parallelism do not exist. The combination of Kammprofile technology and a corrugated design allow this gasket to recover substantially and maintain very stable load-bearing characteristics. The base core material is very thick and resembles what is used with traditional Kammprofile technology. This added substrate thickness, with an exacting corrugated pattern, allows the gasket to recover substantially to maintain very stable load-bearing characteristics.

Lamons® Kammpro® Gasket Family offers numerous solutions for large vessels and equipment that experience movement due to thermal expansion. Kammpro gaskets also provide one of the tightest seals combined with superior load-bearing characteristics. They consist of a metal sealing core (with or without a guide ring) with concentric serrations on both sealing surfaces and faced with a soft material such as flexible graphite, ePTFE, or a Lamons high-temperature gasket (HTG) configuration. Kammpro is the preferred design when improved performance at lower seating stresses is needed, and it can be manufactured in different core materials and shapes with extreme accuracy. It can also be custom engineered to fit various applications.

Flexible Graphite is an all-graphite filler and facing material containing no resins or inorganic fillers. It has outstanding resistance to corrosion against a wide variety of acids, alkalis and salt solutions, organic compounds, and heat transfer fluids, even at high temperatures. There are two proven metal reinforced flexible graphite laminate materials ideal for 95 percent of all sheet gasket applications. Lamons flexible graphite laminates (LG-SS and LG-TC) are surface branded for easy identification.

Polytetrafluoroethylene (PTFE) is the most common thermoplastic gasket material and is also used as a filler. Its outstanding properties include resistance to temperature extremes from cryogenic to 500°F (260°C) and high resistance to chemicals, solvents, caustics, and acids, except free fluorine and alkali metals. It has a very low surface energy and does not adhere to flanges. PTFE gaskets can be supplied in a variety of forms, either as virgin or reprocessed material, and with a variety of filler material. The principal advantage in adding fillers to PTFE is to inhibit cold flow or creep relaxation.

Fasteners

Standard Fasteners are stocked in common sizes and materials for use in hydrogen applications. Carbon steel and stainless steel are the most common alloys, but we offer a variety of other alloys upon request. Whether it’s large or small quantities, or simply a one-off, we can deliver what you need. Our vast inventory of fasteners, stud bolts, eye bolts, threaded bar stock, and related hardware is manufactured in accordance with Six Sigma principles to ensure the highest quality product. Lamons internal quality lab is qualified to ISO 17025, and our quality and testing procedures include positive material identification (PMI), ultrasonic testing (UT), magnetic particle inspection (MPI), and liquid penetrant inspection (LPI). For fasteners, we are certified for ISO 9001:2015, and API 20E and 20F.

Specialty Fasteners are produced in our Houston, Texas facility where we have 30 state-of-the-art computerized numeric control (CNC) machines. Our skilled programmers and machinists produce high-quality, specialty-machined components to precise specifications regardless of quantities. We can produce special requests up to 22” (56 cm) in diameter or 42” (107 cm) in length, with coatings. Some of our specialty fasteners include forged-head studs, double-end and tap-end studs, galvanized and powder-coated parts, PTFE-coated components, and much more.

Load-monitoring fasteners allow users to monitor the clamp load of any bolted joint, whether static or dynamic, by utilizing a user-friendly indicator that specifies the fastener’s load, which relates to ultimate yield strength. Minimal modifications to the bolt assure basic bolt design integrity. This technology means the fastener can be loaded many times as long as the stress remains in the elastic range, meeting the criteria of ASTM F2482. An accurate assessment of loading can also be obtained after the joint has been put into service.

Lamons Services and Technology Offerings

TruFAST™ Re-engineering Services

Our Field Acquired Seal Technology® is a custom engineering process that reproduces undocumented gaskets. By simply providing a picture of an old gasket or a flange rubbing, our engineering team, working with manufacturing, can produce a replacement gasket. Our TruFAST re-engineering services often shortens the reproduction process from weeks or days to hour.

Engineered Solutions

The Lamons engineering team provides custom, engineered solutions that deliver the right product for your application. Our products are highly reliable, expertly produced safety sealing and attachment solutions, and our extensive inventory of raw materials (including centrifugal castings, forgings, and plates) allows us to respond quickly to your projects

Field Support

With 21 global locations, our team is ready to assist you with troubleshooting, torque calculations, failure investigations, on-site support, bolt-up protocols, critical gasket recommendations, expert field measurements, and much more.Specialty-Machined ProductsLamons maintains over 30 state-of-the-art CNC machines. Our programmers and machinists deliver high-quality, machined components with one of the quickest response times in the industry.

Value-Added Benefits

Lamons provides smart technology solutions to help keep you up and running 24/7/365:

- eCatalog eCommerce Solutions – An advanced, highly customizable online shopping catalog that integrates seamlessly with your material requirements planning (MRP) and enterprise resource planning (ERP) systems.

- Drawings Online Repository – Paper drawings converted to electronic files with pertinent details including unit and equipment unique identifiers, kitting of components, part numbers, equipment specifics, required quantities, mechanical details for gaskets, and more. Drawings online can also create custom packing slips and detailed labels.

- Inventory Management System – Rely on Lamons for on-site inventories of your routine parts. Whether inventories are owned or on consignment, you can manage inventory levels, replenish stock, and track material receipts and shipments with our web-based system. Simplify the purchase process even further by integrating our VMI with your ERP system.

- Asset Tracking and Preventive Maintenance System – A desktop and mobile application that allows you to manage your purchased assets, assign unique tracking numbers, save and recall asset-specific documents, define preventive maintenance periods, and more.